- General Industrial

- Aerospace

- Brick & Ceramics

- Chemical & Petrochemical

- Pharmaceutical, Food, Dairy, & Beverage

- Engineering & Architecture (EPC Firms) & Major Equipment OEMs

- Glass

- Incineration

- Metals Manufacturing & Heat Treating

- OEM & Equipment Builders

- Oil & Gas - Downstream & Refining

- Oil & Gas Upstream and Midstream

- Plastics & Fiber / Textiles Industries

- Power

- Pulp & Paper

- Rubber, Cement, & Aggregate

- Semiconductor

- Test & Measurement

- Non-Insulated Single Conductor Thermocouple Type

- Thermocouple Limits of Error and Published Range For Bare Wire

- Thermocouple Sheath Material Temperature Limits

- Thermocouple Temperature Limits By Sheath Diameter

- Base Metal TC Wire

- Comparison of Wire Gauges

- High Temperature Thermocouple Wire Information

- Accuracy of JMS Thermocouple Wire

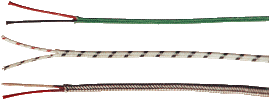

- Thermocouple Type Material & Color Code

- Thermocouple Extension Grade Wire General Information

- Thermocouple Grade Wire General Information

| Thermocouple Type | Material | Magnetic | ASTM Color Coding | IEC Color Coding |

|---|---|---|---|---|

| J |

Iron

Constantan |

Yes

No |

White

Red |

White

Black |

| T |

Copper

Constantan |

No

No |

Blue

Red |

White

Brown |

| K |

Chromel

Alumel |

No

No |

Yellow

Red |

White

Green |

| E | Chromel/Constantan |

No

No |

Purple

Red |

White

Violet |

| P | Platinel | N/A | N/A | N/A |

| S |

Platinum 10% Rhodium

Pure Platinum |

No

No |

Black

Red |

White

Orange |

| R |

Platinum 13% Rhodium

Pure Platinum |

No

No |

Black

Red |

white

Orange |

| B |

Platinum 30% Rhodium

Platinum 6% Rhodium |

No

No |

Grey

Red |

White

Grey |

| N | Nicrosil/Nisil |

No

Slightly |

Orange

Red |

White

Pink |

| C | Tungsten 5% Rhenium/ Tungsten 26% Rhenium |

No

No |

White

Red |

N/A |

| ANSI Thermocouple Type | Temp Range (°C) | Temp Range (°F) | Standard Limits of Error (°C)* | Special Limits of Error (°C) |

|---|---|---|---|---|

| J | 0 to 760 | 32 to 1400 | The greater of ±2.2 or ±0.75% | The greater of ±2.2 or ±0.75% |

| T | 0 to 370 | 32 to 700 | The greater of ±1 or ±0.75% | The greater of ±0.5 or ±0.4% |

| K | 0 to 1260 | 32 to 2300 | The greater of ±2.2 or ±0.75% | The greater of ±1.1 or ±0.4% |

| E | 0 to 870 | 32 to 1600 | The greater of ±1.7 or ±0.5% | The greater of ±1 or ±0.4% |

| S | 0 to 1480 | 32 to 2700 | The greater of ±1.5 or ±0.25% | The greater of ±0.6 or ±0.1% |

| R | 0 to 1480 | 32 to 2700 | The greater of ±1.5 or ±0.25% | The greater of ±0.6 or ±0.1% |

| N | 0 to 1246 | 32 to 2300 | The greater of ±2.2 or ±0.75% | The greater of ±1.1 or ±0.4% |

| B | 870 to 1700 | 1600 to 3100 | ±0.5% | ±0.25% |

| TA | -200 to 0 | -328 to 32 | The greater of ±1 or ±1.5% | B |

| EA | -200 to 0 | -328 to 32 | The greater of ±1.7 or ±1% | B |

| KA | -200 to 0 | -328 to 32 | The greater of ±2.2 or ±2% | B |

A: Thermocouple and thermocouple materials are normally supplied to meet the tolerances specified in the table of temperatures above 0°C. The same materials, however, may not fall within the tolerances given for temperatures below 0°C in the normal section in the table. If materials are required to meet the tolerances stated for temperatures below 0°C the purchase order must specifically state that requirement. Selection of materials will usually be required.

B: Special tolerances for temperatures below 0°C are difficult to justify due to limited available information.

*: Standard and special limits of error in °F are 1.8 times larger thant the °C tolerance at the equivalent °C temperature.

| Material Symbol |

Sheath Material |

Melting Point(°F) |

Max Temp; In Air(°F) |

Atmosphere* |

|---|---|---|---|---|

| H | 304 SS | 2550 | 1650 | ORNV |

| J | 310 SS | 2550 | 2100 | ORNV |

| L | 316L SS | 2550 | 1650 | ORNV |

| O | 446 SS | 2700 | 2100 | ORNV |

| M | Inconel 600 | 2500 | 2100 | ONV |

| P | Inconel 702 | 2620 | 1500 | ONV |

| Q | Platinum | 3216 | 3000 | ON |

| R | Molybdenum | 4750 | 1000 | VNR |

| T | Titanium | 3300 | 600 | V |

| V | STABALOY | 2552 | 2220 | ORNV |

*KEY

O=Oxidizing, R=Reducing, N=Neutral, V=Vacuum

| Suggested Upper Limit for Outside Diameter (Single Element) °C (°F) | ||||||

|---|---|---|---|---|---|---|

| Sheath | Thermocouple Type | |||||

| In | mm | T | J | E | K | N |

| 1/25" | 1.0 | 260° (500°) | 260° (500°) | 300° (570°) | 700° (1290°) | 2700° (1290°) |

| 1/16" | 1.6 | 260° (500°) | 440° (825°) | 510° (950°) | 920° (1690°) | 920° (1690°) |

| 1/8" | 3.2 | 315° (600°) | 520° (970°) | 650° (1200°) | 1070° (1950°) | 1070° (1950°) |

| 3/16" | 4.8 | 370° (700°) | 620° (1150°) | 730° (1350°) | 1150° (2100°) | 1150° (2100°) |

| 1/4" | 6.3 | 370° (700°) | 720° (1330°) | 820° (1510°) | 1150° (2100°) | 1150° (2100°) |

| 3/8" | 9.5 | 370° (700°) | 720° (1330°) | 820° (1510°) | 1150° (2100°) | 1150° (2100°) |

BASE METAL THERMOCOUPLE WIRE FT. / LB

| ANSI CODE | WIRE TYPE | ELEMENT POLARITY | AWG | WIRE FT. / LB |

|---|---|---|---|---|

| JP | Iron | JP Iron Positive (+) 8 | 8 14 20 24 28 30 |

22.8 91.2 365.0 925.0 2353.0 3767.0 |

| JN | Constantan | Negative (- | 8 14 20 24 28 30 |

20.2 80.9 324.0 821.0 2089.0 3316.0 |

| KP | Chrome | Positive (+) | 8 14 20 24 28 30 |

21 83 331 838 2089 3316 |

| KN | Alumel | Negative (-) | 8 14 20 24 28 30 |

21 83 331 838 2130 3370 |

| EP | ||||

| EN | Chromel | Positive (+) | 20 24 30 |

328 833 3364 |

| TP | Copper | Positive (+) | 20 24 30 |

324 820 3294 |

| TN | Constantan | Negative (-) | 20 24 30 |

324 821 3316 |

COMPARISON OF WIRE GAUGES

Standard Wire Gauges in Approximate Decimals of an Inch and mm.

| American or Brown and Sharp Wire Gauge | Diameter Inches | Diameter Millimeters | British Standard or Imperial | US Standard |

|---|---|---|---|---|

| 1 | 0.2893 | 7.348 | .300 | .281 |

| 2 | 0.2576 | 6.544 | .276 | .266 |

| 3 | 0.2294 | 5.827 | .252 | .250 |

| 4 | 0.2043 | 5.189 | .232 | .234 |

| 5 | 0.1819 | 4.621 | .212 | .219 |

| 6 | 0.1620 | 4.115 | .192 | .203 |

| 7 | 0.1443 | 3.665 | .176 | .188 |

| 8 | 0.1285 | 3.264 | .160 | .172 |

| 9 | 0.1144 | 2.906 | .144 | .156 |

| 10 | 0.1019 | 2.588 | .128 | .141 |

| 11 | 0.0907 | 2.304 | .116 | .125 |

| 12 | 0.0808 | 2.053 | .104 | .109 |

| 13 | 0.0720 | 1.829 | .092 | .0938 |

| 14 | 0.0641 | 1.628 | .080 | .0781 |

| 15 | 0.0571 | 1.450 | .072 | .0703 |

| 16 | 0.0508 | 1.291 | .064 | .0625 |

| 17 | 0.0453 | 1.150 | .056 | .0563 |

| 18 | 0.0403 | 1.024 | .048 | .0500 |

| 19 | 0.0359 | 0.9116 | .040 | .0438 |

| 20 | 0.0320 | 0.8118 | .036 | .0375 |

| 21 | 0.0285 | 0.7230 | .032 | .0344 |

| 22 | 0.0253 | 0.6438 | .028 | .031 |

| 23 | 0.0226 | 0.5733 | .024 | .0281 |

| 24 | 0.0201 | 0.5106 | .022 | .0250 |

| 25 | 0.0179 | 0.4547 | .020 | .0219 |

| 26 | 0.0159 | 0.4049 | .018 | .0188 |

| 27 | 0.0142 | 0.3606 | .0164 | .0172 |

| 28 | 0.0126 | 0.3211 | .0148 | .0156 |

| 29 | 0.0113 | 0.2859 | .0136 | .0141 |

| 30 | 0.0100 | 0.2546 | .0124 | .0125 |

| 31 | 0.0089 | 0.2268 | .0116 | .0109 |

| 32 | 0.0080 | 0.2019 | .0108 | .0102 |

| 33 | 0.00708 | 0.178 | .010 | .0094 |

| 34 | 0.00630 | 0.152 | .0092 | .0086 |

| 35 | 0.00561 | 0.138 | .0084 | .0078 |

| 36 | 0.00500 | 0.127 | .0076 | .0066 |

| 37 | 0.00445 | 0.1131 | .0068 | .0070 |

| 38 | 0.00397 | 0.1007 | .006 | .0063 |

| 39 | 0.00353 | 0.08969 | .0052 | -- |

| 40 | 0.00314 | 0.07987 | .0048 | -- |

HIGH TEMPERATURE THERMOCOUPLE WIRE

| ANSI CODE | CODE TYPE | ELEMENT POLARITY | AWG | WIRE IN / T. OZ |

|---|---|---|---|---|

| SP | Pt-10% Rh | Positive (+) | 16 20 24 26 28 |

46.4 118.0 302.2 480.0 715.2 |

| SN | ||||

| RP | Pt | Negative (-) | 16 20 24 26 28 |

43.3 110.0 281.6 432.0 666.6 |

| RN | Pt | Negative (-) | 16 20 24 26 28 |

43.3 110.0 281.6 432.0 666.6 |

| BP | Pt-30% Rh | Positive (+) | 16 20 24 28 |

52.7 134.0 343.1 812.3 |

| BN | Pt-6% Rh | Negative (-) | 16 20 24 28 |

45.2 114.8 394.0 695.8 |

| CP | Tungsten 5% Rhenium | Positive (+) | 24 | 308.7 |

| CN | Tungsten 26% Rhenium | Negative (-) | <24> | 304.3 |

Pt = Platinum

Rh = Rhodium

ACCURACY OF JMS THERMOCOUPLE WIRE

JMS insulated and bare thermocouple wire is matched to meet standard or special limits of error for temperatures above 32°F (0°C), as given in ANSI MC 96.1 and shown in tables below

LIMITS OF ERROR FOR THERMOCOUPLE WIRE

| THERMOCOUPLE TYPE | °F | |||||

|---|---|---|---|---|---|---|

| WIRE ALLOY | ANSI TYPE SYMBOL | TEMPERATURE RANGE °F | STANDARD LIMITS | ORDER CODE | SPECIAL LIMITS | ORDER CODE |

| Iron (+) vs. Constantan (-) | J | +32° to +545° +545° to +1400° |

±4° ±.75% |

J | ±2° ±.4% |

JJ |

| Chromel™ (+) vs. Alumel ™ (-) | K | 330° to -165° -165° to +32° +32° to +545° +545° to +2300° |

±2% ±4° ±4° ±.75% |

K | ±2° ±.4% |

KK |

| Copper (+) vs. Constantan™ (- | T | -330° to -85° -85° to +270° +270° to +660° |

±1.5% ±1.8° ±.75% |

T | ±.8% ±.9° ±.4% |

TT |

| Chromel™ (+) vs. Constantan™ (-) | E | -330° to -270° -270° to +480° +480° to +640° +640° to +1600° |

±1% ±3° ±3° ±5% |

E | ±1.8° ±1.8° ±.4% ±.4% |

EE |

| Nicrosil™ (+) vs. Nisil™ (-) | N | +32° to +545° +545° to +2300° |

±4° ±.75% |

N | ±2° ±.4% |

NN |

| THERMOCOUPLE TYPE | °C | |||||

|---|---|---|---|---|---|---|

| WIRE ALLOY | ANSI TYPE SYMBOL | TEMPERATURE RANGE °C | STANDARD LIMITS | ORDER CODE | SPECIAL LIMITS | ORDER CODE |

| Iron (+) vs. Constantan (-) | J | 0° to +285° +285° to +750 |

±2.2° ±.75% |

J | ±1.1° ±.4% |

JJ |

| Chromel™ (+) vs. Alumel ™ (-) | K | -200° to -110° -110° to 0° 0° to +285° +285° to +1250 |

±2% ±2.2° ±2.2° ±.75% |

K | ±1.1° ±.4% |

KK |

| Copper (+) vs. Constantan™ (-) | T | -200° to -65° -65° to +130° +130° to +350° |

±1.5% ±1° ±.75% |

T | ±.8% ±.5° ±.4% |

TT |

| Chromel™ (+) vs. Constantan™ (-) | E | -200° to -170° -170° to +250° +250° to +340° +340° to +900° |

±1% ±1.7° ±1.7° ±5% |

E | ±1° ±1° ±.4% ±.4% |

EE |

| Nicrosil™ (+) vs. Nisil™ (-) | N | 0° to +285° +285° to +1250° |

±2.2° ±.75% |

N | ±1.1° ±.4% |

NN |

| Thermocouple Type | Material | Magnetic | ASTM Color Coding | IEC Color Coding |

| J | Iron Constantan | Yes No |

White Red |

White Black |

| T | Copper Constantan | No No |

Blue Red |

White Brown |

| K | Chromel Alumel | No No |

Yellow Red |

White Green |

| E | Chromel/Constantan | No No |

Purple Red |

White Violet |

| P | Platinel | N/A | N/A | N/A |

| S | Platinum 10% Rhodium Pure Platinum | No No |

Black Red |

White Orange |

| R | Platinum 13% Rhodium Pure Platinum | No No |

Black Red |

white Orange |

| B | Platinum 30% Rhodium Platinum 6% Rhodium | No No |

Grey Red |

White Grey |

| N | Nicrosil/Nisil | No Slightly |

Orange Red |

White Pink |

| C | Tungsten 5% Rhenium/ Tungsten 26% Rhenium | No No |

White Red |

N/A |

| ANSI: TYPE, J - Iron / Constantan | |||||||

|---|---|---|---|---|---|---|---|

| Catalog Number | Guage Size | Conductors | *Ohms | Primary Insulation | Outer Jacket | Min-Max. O.D. | Est. Shpg. Wt. per M |

| PP161JX | 16 | Solid | .137 | Polyvinyl Chloride | Polyvinyl Chloride | .111 x .188” | 27 lbs. |

| PA161JX | 16 | Solid | .137 | PVC/Alum. Mylar Shield (Twisted) | PVC | .222” | 28 lbs. |

| PA201JX | 20 | Solid | .357 | PVC/Alum. Mylar Shield (Twisted) | PVC | .184” | 20 lbs. |

| PP201JX | 20 | Solid | .357 | Polyvinyl Chloride | Polyvinyl Chloride | .095 x .158” | 14 lbs. |

| PP202JX | 20 | Stranded | .317 | Polyvinyl Chloride | Polyvinyl Chloride | .115 x .190” | 14 lbs. |

| PX201JX | 20 | Solid | .357 | (FEP) Extruded Teflon | Extruded Teflon | .072 x .124” | 11 lbs. |

| ANSI: TYPE, K - Chromel / Alumel | |||||||

|---|---|---|---|---|---|---|---|

| Catalog Number | Guage Size | Conductors | *Ohms | Primary Insulation | Outer Jacket | Min-Max. O.D. | Est. Shpg. Wt. per M |

| PA161KX | 16 | Solid | .233 | PVC/Alum. Mylar Shield (Twisted) | PVC | .222” | 28 lbs. |

| PP161KX | 16 | Solid | .233 | Polyvinyl Chloride | Polyvinyl Chloride | .116 x .188” | 27 lbs. |

| PA201KX | 20 | Solid | .590 | PVC/Alum. Mylar Shield (Twisted) | PVC | .184” | 20 lbs. |

| PP201KX | 20 | Solid | .590 | Polyvinyl Chloride | Polyvinyl Chloride | .195 x .158” | 14 lbs. |

| PP202KX | 20 | Stranded | .538 | Polyvinyl Chloride | Polyvinyl Chloride | .115 x .190” | 14 lbs. |

| ANSI: TYPE, T - Copper / Constantan | |||||||

|---|---|---|---|---|---|---|---|

| Catalog Number | Guage Size | Conductors | *Ohms | Primary Insulation | Outer Jacket | Min-Max. O.D. | Est. Shpg. Wt. per M |

| PP141TX | 14 | Solid | .074 | Polyvinyl Chloride | Polyvinyl Chloride | .130 x .226” | 37 lbs. |

| PA161TX | 16 | Solid | .118 | PVC/Alum. Mylar Shield (Twisted) | PVC | .222” | 20 lbs |

| PP161TX | 16 | Solid | .118 | Polyvinyl Chloride | Polyvinyl Chloride | .111 x .188” | 28 lbs. |

| PA201TX | 20 | Solid | .298 | PVC/Alum. Mylar Shield | PVC | .184” | 20 lbs. |

| PP201TX | 20 | Solid | .298 | Polyvinyl Chloride | Polyvinyl Chloride | .095 x .158” | 15 lbs. |

| ANSI: TYPE, E - Chromel / Constantan | |||||||

|---|---|---|---|---|---|---|---|

| Catalog Number | Guage Size | Conductors | *Ohms | Primary Insulation | Outer Jacket | Min-Max. O.D. | Est. Shpg. Wt. per M |

| PA161EX | 16 | Solid | .278 | PVC/Alum. Mylar Shield (Twisted) | PVC | .222” | 20 lbs. |

| PP201EX | 20 | Solid | .704 | Polyvinyl Chloride | Polyvinyl Chloride | .095 x .158” | 15 lbs. |

| ANSI: TYPE, S and R - Platinum / Rhodium | |||||||

|---|---|---|---|---|---|---|---|

| Catalog Number | Guage Size | Conductors | *Ohms | Primary Insulation | Outer Jacket | Min-Max. O.D. | Est. Shpg. Wt. per M |

| PP161SX | 16 | Solid | .016 | Polyvinyl Chloride | Polyvinyl Chloride | .116 x .250” | 27 lbs. |

| GG201SX | 20 | Solid | .040 | Glass Braid | Glass Braid | .059 x .105” | 8 lbs. |

| PP201SX | 20 | Solid | .040 | Polyvinyl Chloride | Polyvinyl Chloride | .095 x .158 | 14 lbs. |

*ohms per double foot at 20°C (68°F).

| ANSI: TYPE, J - Iron / Constantan | |||||||

|---|---|---|---|---|---|---|---|

| Catalog Number | Guage Size | Conductors | *Ohms | Primary Insulation | Outer Jacket | Min-Max. O.D. | Est. Shpg. Wt. per M |

| GG210J | 20 | Solid | .357 | Glass Braid | Glass Braid | .059 x .105” | 8 lbs. |

| GG202J | 20 | Stranded | .317 | Double Glass Braid | Glass Braid | .075 x .137” | 9lbs. |

| KK201J | 20 | Solid | .357 | Fused Kapton Tape | None, Twisted | .087” | 10 lbs. |

| NN201J | 20 | Solid | .357 | Nylon | Nylon | .068 x .120” | 11 lbs. |

| TF201J | 20 | Solid | .357 | (TFE) tape, Teflon | (TFE) tape, Teflon | .065 x .110” | 10 lbs. |

| TX201J | 20 | Solid | .357 | Extruded (FEP) Teflon | Extruded (FEP) Teflon | .072 x .124” | 11 lbs. |

| GG241J | 24 | Solid | .877 | Glass Braid | Glass Braid | .047 x .081” | 4 lbs. |

| KK241J | 24 | Solid | .877 | Fused Kapton Tape | None, Twisted | .063” | 5 lbs. |

| PP241J | 24 | Solid | .877 | Polyvinyl Chloride | None, Rip-Cord | .048 x .096” | 4 lbs. |

| TF241J | 24 | Solid | .877 | (TFE) tape, Teflon | (TFE) tape, Teflon | .047 x .078” | 5 lbs. |

| GG261J | 26 | Solid | 1.394 | Glass Wrap | Glass Braid | .040 x .065” | 3 lbs. |

| GG281J | 28 | Solid | 2.216 | Glass Wrap | Glass Braid | .037 x .059” | 3 lbs. |

| GG301J | 30 | Solid | 3.520 | Glass Wrap (Braid avail.) | Glass Braid | .033 x .053” | 3 lbs. |

| ANSI: TYPE, K - Chromel / Alumel | |||||||

|---|---|---|---|---|---|---|---|

| Catalog Number | Guage Size | Conductors | *Ohms | Primary Insulation | Outer Jacket | Min-Max. O.D. | Est. Shpg. Wt. per M |

| GG201K | 20 | Solid | .590 | Glass Braid | Glass Braid | .059 x .105” | 8 lbs. |

| GG202K | 20 | Stranded | .538 | Double Glass Braid | Glass Braid | .075 x .137” | 9 lbs. |

| KK201K | 20 | Solid | .590 | Fused Kapton Tape | None, Twisted | .087” | 10 lbs. |

| RR201K | 20 | Solid | .590 | Vitreous Silica Braid | Vitreous Silica Braid | .102 x .174” | 16 lbs. |

| TF201K | 20 | Solid | .590 | (TFE) tape, Teflon | (TFE) tape, Teflon | .065 x .110” | 10 lbs. |

| TX201K | 20 | Solid | .590 | Teflon Extruded (FEP) | Teflon Extruded | .072 x .124” | 11 lbs. |

| GG241K | 24 | Solid | 1.490 | Glass Braid (Wrap avail.) | Glass Braid | .047 x .081” | 4 lbs. |

| PP241K | 24 | Solid | 1.490 | Polyvinyl-Rip Cord Const. | None | .048 x .096” | 4 lbs. |

| GG261K | 26 | Solid | 2.370 | Glass Wrap | Glass Braid | .040 x .065” | 3 lbs. |

| GG281K | 28 | Solid | 3.770 | Glass Braid (Wrap avail.) | Glass Braid | .039 x .064” | 3 lbs. |

| GG301K | 30 | Solid | 5.980 | Glass Wrap | Glass Braid | .033 x .053” | 2 lbs. |

| ANSI: TYPE, T - Copper / Constantan | |||||||

|---|---|---|---|---|---|---|---|

| Catalog Number | Guage Size | Conductors | *Ohms | Primary Insulation | Outer Jacket | Min-Max. O.D. | Est. Shpg. Wt. per M |

| GG201T | 20 | Solid | .298 | Glass Braid (Wrap avail.) | Glass Braid | .059 x .105” | 5 lbs |

| TF201T | 20 | Solid | .298 | (TFE) tape, Teflon | (TFE) tape, Teflon | .065 x .110” | 10 lbs. |

| TX201T | |||||||

| GG241T | 20 | Solid | .298 | Extruded Teflon (FEP) | Extruded Teflon | .072 x .124” | 11 lbs. |

| NN241T | |||||||

| PP241T | 24 | Solid | .753 | Nylon | Nylon | .060 x .095” | 6 lbs. |

| TF241T | 24 | Solid | .753 | (TFE) tape, Teflon | (TFE) tape, Teflon | .047 x .078” | 5 lbs. |

| GG281T | 28 | Solid | 1.905 | Glass Braid (Wrap avail.) | Glass Braid | .039 x .064” | 3 lbs. |

| GG301T | 30 | Solid | 3.025 | Glass Wrap | Glass Braid | .033 x .053” | 2 lbs. |

| ANSI: TYPE, E - Chromel / Constantan | |||||||

|---|---|---|---|---|---|---|---|

| Catalog Number | Guage Size | Conductors | *Ohms | Primary Insulation | Outer Jacket | Min-Max. O.D. | Est. Shpg. Wt. per M |

| GG201E | 20 | Solid | .704 | Glass Braid | Glass Braid | .059 x .105” | 8 lbs. |

| GG241E | 24 | Solid | 1.780 | Glass Braid | Glass Braid | .047 x .081” | 4 lbs. |

*ohms per double foot at 20°C (68°F).