- General Industrial

- Aerospace

- Brick & Ceramics

- Chemical & Petrochemical

- Pharmaceutical, Food, Dairy, & Beverage

- Engineering & Architecture (EPC Firms) & Major Equipment OEMs

- Glass

- Incineration

- Metals Manufacturing & Heat Treating

- OEM & Equipment Builders

- Oil & Gas - Downstream & Refining

- Oil & Gas Upstream and Midstream

- Plastics & Fiber / Textiles Industries

- Power

- Pulp & Paper

- Rubber, Cement, & Aggregate

- Semiconductor

- Test & Measurement

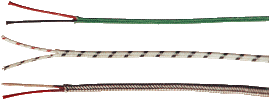

- Thermocouple Type Material & Color Code

- Thermocouple Limits of Error and Published Range For Bare Wire

- Thermocouple Sheath Material Temperature Limits

- Thermocouple Temperature Limits By Sheath Diameter

| Thermocouple Type | Material | Magnetic | ASTM Color Coding | IEC Color Coding |

| J | Iron Constantan | Yes No |

White Red |

White Black |

| T | Copper Constantan | No No |

Blue Red |

White Brown |

| K | Chromel Alumel | No No |

Yellow Red |

White Green |

| E | Chromel/Constantan | No No |

Purple Red |

White Violet |

| P | Platinel | N/A | N/A | N/A |

| S | Platinum 10% Rhodium Pure Platinum | No No |

Black Red |

White Orange |

| R | Platinum 13% Rhodium Pure Platinum | No No |

Black Red |

white Orange |

| B | Platinum 30% Rhodium Platinum 6% Rhodium | No No |

Grey Red |

White Grey |

| N | Nicrosil/Nisil | No Slightly |

Orange Red |

White Pink |

| C | Tungsten 5% Rhenium/ Tungsten 26% Rhenium | No No |

White Red |

N/A |

| ANSI Thermocouple Type | Temp Range (°C) | Temp Range (°F) | Standard Limits of Error (°C)* | Special Limits of Error (°C) |

|---|---|---|---|---|

| J | 0 to 760 | 32 to 1400 | The greater of ±2.2 or ±0.75% | The greater of ±2.2 or ±0.75% |

| T | 0 to 370 | 32 to 700 | The greater of ±1 or ±0.75% | The greater of ±0.5 or ±0.4% |

| K | 0 to 1260 | 32 to 2300 | The greater of ±2.2 or ±0.75% | The greater of ±1.1 or ±0.4% |

| E | 0 to 870 | 32 to 1600 | The greater of ±1.7 or ±0.5% | The greater of ±1 or ±0.4% |

| S | 0 to 1480 | 32 to 2700 | The greater of ±1.5 or ±0.25% | The greater of ±0.6 or ±0.1% |

| R | 0 to 1480 | 32 to 2700 | The greater of ±1.5 or ±0.25% | The greater of ±0.6 or ±0.1% |

| N | 0 to 1246 | 32 to 2300 | The greater of ±2.2 or ±0.75% | The greater of ±1.1 or ±0.4% |

| B | 870 to 1700 | 1600 to 3100 | ±0.5% | ±0.25% |

| TA | -200 to 0 | -328 to 32 | The greater of ±1 or ±1.5% | B |

| EA | -200 to 0 | -328 to 32 | The greater of ±1.7 or ±1% | B |

| KA | -200 to 0 | -328 to 32 | The greater of ±2.2 or ±2% | B |

A: Thermocouple and thermocouple materials are normally supplied to meet the tolerances specified in the table of temperatures above 0°C. The same materials, however, may not fall within the tolerances given for temperatures below 0°C in the normal section in the table. If materials are required to meet the tolerances stated for temperatures below 0°C the purchase order must specifically state that requirement. Selection of materials will usually be required.

B: Special tolerances for temperatures below 0°C are difficult to justify due to limited available information.

*: Standard and special limits of error in °F are 1.8 times larger thant the °C tolerance at the equivalent °C temperature.

| Material Symbol |

Sheath Material |

Melting Point(°F) |

Max Temp; In Air(°F) |

Atmosphere* |

|---|---|---|---|---|

| H | 304 SS | 2550 | 1650 | ORNV |

| J | 310 SS | 2550 | 2100 | ORNV |

| L | 316L SS | 2550 | 1650 | ORNV |

| O | 446 SS | 2700 | 2100 | ORNV |

| M | Inconel 600 | 2500 | 2100 | ONV |

| P | Inconel 702 | 2620 | 1500 | ONV |

| Q | Platinum | 3216 | 3000 | ON |

| R | Molybdenum | 4750 | 1000 | VNR |

| T | Titanium | 3300 | 600 | V |

| V | STABALOY | 2552 | 2220 | ORNV |

*KEY

O=Oxidizing, R=Reducing, N=Neutral, V=Vacuum

| Suggested Upper Limit for Outside Diameter (Single Element) °C (°F) | ||||||

|---|---|---|---|---|---|---|

| Sheath | Thermocouple Type | |||||

| In | mm | T | J | E | K | N |

| 1/25" | 1.0 | 260° (500°) | 260° (500°) | 300° (570°) | 700° (1290°) | 2700° (1290°) |

| 1/16" | 1.6 | 260° (500°) | 440° (825°) | 510° (950°) | 920° (1690°) | 920° (1690°) |

| 1/8" | 3.2 | 315° (600°) | 520° (970°) | 650° (1200°) | 1070° (1950°) | 1070° (1950°) |

| 3/16" | 4.8 | 370° (700°) | 620° (1150°) | 730° (1350°) | 1150° (2100°) | 1150° (2100°) |

| 1/4" | 6.3 | 370° (700°) | 720° (1330°) | 820° (1510°) | 1150° (2100°) | 1150° (2100°) |

| 3/8" | 9.5 | 370° (700°) | 720° (1330°) | 820° (1510°) | 1150° (2100°) | 1150° (2100°) |