- General Industrial

- Aerospace

- Brick & Ceramics

- Chemical & Petrochemical

- Pharmaceutical, Food, Dairy, & Beverage

- Engineering & Architecture (EPC Firms) & Major Equipment OEMs

- Glass

- Incineration

- Metals Manufacturing & Heat Treating

- OEM & Equipment Builders

- Oil & Gas - Downstream & Refining

- Oil & Gas Upstream and Midstream

- Plastics & Fiber / Textiles Industries

- Power

- Pulp & Paper

- Rubber, Cement, & Aggregate

- Semiconductor

- Test & Measurement

- Thermocouple Type Material & Color Code

- Thermocouple Sheath Material Temperature Limits

- Thermocouple Temperature Limits By Sheath Diameter

- Thermocouple Limits of Error and Published Range For Bare Wire

- RTD Standards

- RTD Tolerances

- Wire Insulation Material

- Non-Insulated Single Conductor Thermocouple Type

| Thermocouple Type | Material | Magnetic | ASTM Color Coding | IEC Color Coding |

| J | Iron Constantan | Yes No |

White Red |

White Black |

| T | Copper Constantan | No No |

Blue Red |

White Brown |

| K | Chromel Alumel | No No |

Yellow Red |

White Green |

| E | Chromel/Constantan | No No |

Purple Red |

White Violet |

| P | Platinel | N/A | N/A | N/A |

| S | Platinum 10% Rhodium Pure Platinum | No No |

Black Red |

White Orange |

| R | Platinum 13% Rhodium Pure Platinum | No No |

Black Red |

white Orange |

| B | Platinum 30% Rhodium Platinum 6% Rhodium | No No |

Grey Red |

White Grey |

| N | Nicrosil/Nisil | No Slightly |

Orange Red |

White Pink |

| C | Tungsten 5% Rhenium/ Tungsten 26% Rhenium | No No |

White Red |

N/A |

| Material Symbol |

Sheath Material |

Melting Point(°F) |

Max Temp; In Air(°F) |

Atmosphere* |

|---|---|---|---|---|

| H | 304 SS | 2550 | 1650 | ORNV |

| J | 310 SS | 2550 | 2100 | ORNV |

| L | 316L SS | 2550 | 1650 | ORNV |

| O | 446 SS | 2700 | 2100 | ORNV |

| M | Inconel 600 | 2500 | 2100 | ONV |

| P | Inconel 702 | 2620 | 1500 | ONV |

| Q | Platinum | 3216 | 3000 | ON |

| R | Molybdenum | 4750 | 1000 | VNR |

| T | Titanium | 3300 | 600 | V |

| V | STABALOY | 2552 | 2220 | ORNV |

*KEY

O=Oxidizing, R=Reducing, N=Neutral, V=Vacuum

| Suggested Upper Limit for Outside Diameter (Single Element) °C (°F) | ||||||

|---|---|---|---|---|---|---|

| Sheath | Thermocouple Type | |||||

| In | mm | T | J | E | K | N |

| 1/25" | 1.0 | 260° (500°) | 260° (500°) | 300° (570°) | 700° (1290°) | 2700° (1290°) |

| 1/16" | 1.6 | 260° (500°) | 440° (825°) | 510° (950°) | 920° (1690°) | 920° (1690°) |

| 1/8" | 3.2 | 315° (600°) | 520° (970°) | 650° (1200°) | 1070° (1950°) | 1070° (1950°) |

| 3/16" | 4.8 | 370° (700°) | 620° (1150°) | 730° (1350°) | 1150° (2100°) | 1150° (2100°) |

| 1/4" | 6.3 | 370° (700°) | 720° (1330°) | 820° (1510°) | 1150° (2100°) | 1150° (2100°) |

| 3/8" | 9.5 | 370° (700°) | 720° (1330°) | 820° (1510°) | 1150° (2100°) | 1150° (2100°) |

| ANSI Thermocouple Type | Temp Range (°C) | Temp Range (°F) | Standard Limits of Error (°C)* | Special Limits of Error (°C) |

|---|---|---|---|---|

| J | 0 to 760 | 32 to 1400 | The greater of ±2.2 or ±0.75% | The greater of ±2.2 or ±0.75% |

| T | 0 to 370 | 32 to 700 | The greater of ±1 or ±0.75% | The greater of ±0.5 or ±0.4% |

| K | 0 to 1260 | 32 to 2300 | The greater of ±2.2 or ±0.75% | The greater of ±1.1 or ±0.4% |

| E | 0 to 870 | 32 to 1600 | The greater of ±1.7 or ±0.5% | The greater of ±1 or ±0.4% |

| S | 0 to 1480 | 32 to 2700 | The greater of ±1.5 or ±0.25% | The greater of ±0.6 or ±0.1% |

| R | 0 to 1480 | 32 to 2700 | The greater of ±1.5 or ±0.25% | The greater of ±0.6 or ±0.1% |

| N | 0 to 1246 | 32 to 2300 | The greater of ±2.2 or ±0.75% | The greater of ±1.1 or ±0.4% |

| B | 870 to 1700 | 1600 to 3100 | ±0.5% | ±0.25% |

| TA | -200 to 0 | -328 to 32 | The greater of ±1 or ±1.5% | B |

| EA | -200 to 0 | -328 to 32 | The greater of ±1.7 or ±1% | B |

| KA | -200 to 0 | -328 to 32 | The greater of ±2.2 or ±2% | B |

A: Thermocouple and thermocouple materials are normally supplied to meet the tolerances specified in the table of temperatures above 0°C. The same materials, however, may not fall within the tolerances given for temperatures below 0°C in the normal section in the table. If materials are required to meet the tolerances stated for temperatures below 0°C the purchase order must specifically state that requirement. Selection of materials will usually be required.

B: Special tolerances for temperatures below 0°C are difficult to justify due to limited available information.

*: Standard and special limits of error in °F are 1.8 times larger thant the °C tolerance at the equivalent °C temperature.

| Organization | Standard | Alpha | Nominal Resistance(ohms) At 0°C |

|---|---|---|---|

| International Electrotechnical Commission (Supersedes BS & DIN) |

IEC 60751: 2022 | 0.00385 |

100 |

| ASTM International | ASTM E1137/E1137M-08 (2020) | 0.00385 | 100 |

| American Scientific Apparatus Makers Association (SAMA) |

RC21-4-1966 | 0.003923 | 98.129 |

| British Standards Association |

b.S. 1904-1964 | 0.00385 | 100 |

| Normenstelle Elektrotechnik |

DIN 43760 | 0.00385 | 100 |

| US Department of Defense |

MIL-T-24388 | 0.00392 | 100 |

Tolerance Classes for Wound Resistors

| Tolerance Class | Tolerance Value (°C) | Temperature Range of Validity of Tolerances |

|---|---|---|

| W 0.1 | ±(0.1° + 0.0017[t]) | -50° to 250° |

| W 0.15 | ±(0.15° + 0.002[t]) | -100° to 450° |

| W 0.3 | ±(0.3° + 0.005[t]) | -196° to 661° |

| W 0.6 | ±(0.6° + 0.01[t]) | -196° to 661° |

Tolerance Classes for Film Resistors

| Tolerance Class | Tolerance Value (°C) | Temperature Range of Validity of Tolerances |

|---|---|---|

| F 0.1 | ±(0.1° + 0.0017[t]) | -50° to 250° |

| F 0.15 | ±(0.15° + 0.002[t]) | -50° to 450° |

| F 0.3 | ±(0.3° + 0.005[t]) | -50° to 661° |

| F 0.6 | ±(0.6° + 0.01[t]) | -50° to 661° |

Tolerance Classes for Thermometers (Finished Probes)

| Tolerance Class | Tolerance Value (°C) | Temperature Range of Validity of Tolerances |

|---|---|---|

| AA | ±(0.1° + 0.0017[t]) | -50° to 250° |

| A | ±(0.13° + 0.0017[t]) | -100° to 450° |

| B | ±(0.25° + 0.0042[t]) | -196° to 600° |

| C | ±(0.6° + 0.01[t]) | -196° to 600° |

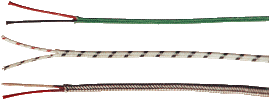

WIRE INSULATION MATERIAL

POLYVINYL CHLORIDE INSULATED WIRE

Polyvinyl Chloride-Polyvinyl Chloride - PP

Color-coded polyvinyl chloride is extruded on each individual conductor and on the outer jacket. It has dielectric and mechanical strength, plus flexibility. PVC is resistant to flame, moisture and abrasion. It is also inexpensive and easily pulled through a conduit. lt is offered in thermocouple extension grade. Temperature rating: Continuous: -20 to +221°F (-29 to 105°C)

Polyvinyl Chloride Rip-Cord Construction - PC

Polyvinyl chloride is extruded on both positive and negative conductors simultaneously to form a rip-cord construction. Offered in thermocouple grade 24 gauge solid conductors. Temperature rating: Continuous: -20 to +221°F (-29 to 105°C)

Polyvinyl Chloride with Twisted Conductors, Aluminum Mylar* Shield, and Drain Wire - PA

Polyvinyl chloride insulates the positive and negative conductors. The conductors are then twisted and helically wrapped with an aluminum backed Mylar* tape. A bare copper drain wire runs through the construction in contact with the aluminum tape furnishing a low resistance path to ground. The twisted shield provides electrostatic interference rejection. The outer jacket is of polyvinyl chloride which has excellent mechanical strength. Wire is resistant to flame, moisture, and abrasion. Offered in extension grade. Thermocouple grade available upon request. Temperature rating: Continuous: Up to 176°F and 80°C

*Trade name of DuPont.

KAPTON INSULATED WIRE

Kapton - KK

Kapton polyimide film is applied to both the positive and negative conductor or just to the positive conductor. Kapton is highly resistive to abrasion, radiation and is non-flammable. Excellent for use in extremely harsh environments. No ISA/ ASTM color code. Kapton has no known organic solvents. Kapton is an excellent choice for cryogenic environments because its insulating characteristics remain intact at lower temperatures. Offered in thermocouple grade. Temperature rating: Continuous: Up to 550°F (285°C). Intermittent: Up to 750°F (400°C).

NYLON INSULATED WIRE

Nylon-Nylon - NN

Color-coded nylon is extruded on both positive and negative conductors with a nylon outer jacket. This insulation has excellent abrasion resistance, excellent chemical resistance, and poor moisture resistance. Offered in thermocouple grade. Temperature rating: Continuous: Up to 350°F and 177°C.

TEFLON INSULATED WIRE

Teflon (extruded) Teflon (extruded) - TT

Color-coded Teflon (FEP)* is extruded on the positive and negative conductors and outer jacket. This insulation is unaffected by most corrosive substances, outdoor weather, or lubricants. It is flame resistant and heat aging will not cause embrittlement or cracking. Good for cryogenic applications. Offered in thermocouple grade. Temperature rating: Continuous: Up to 400°F (200°C).

Teflon (Fused TFE Tape) Teflon (Fused TFE Tape) - TF

TFE tape is spirally applied to the conductor and heated. This process fuses the tape into a homogeneous layer of TFE. Fused teflon wire offers good abrasion resistance and excellent resistance to both moisture and chemicals. Offered in thermocouple grade. Temperature rating: Continuous: Up to 500°F (260°C).

*DuPont Trademark

FIBROUS INSULATED WIRE

Fiberglass Braid - GG

Glass braid on individual conductors with glass braid outer jacket. Designed for continuous use in high temperature applications. Poor abrasion and moisture resistance. Offered in thermocouple grade. Temperature rating: Continuous: Up to 900°F (482°C). Intermittent: Up to 1000°F (529°C).

Hightemp Fiberglass Braid - HG

A high temperature fiberglass braid is applied over each conductor and then impregnated with a binder. Although the binder improves resistance to abrasion and moisture, it is destroyed above 400°F (204°C). Offered in thermocouple grade. Temperature rating: Continuous: Up to 1300°F (705°C). Intermittent: Up to 1600°F (871°C). We recommend SS overbraid with this wire (Ordering Code HS).

Fiberglass and Hightemp Fiberglass Braid with Stainless Steel Overbraid - GS and HS

A stainless steel overbraid is applied to fiberglass (Ordering Code GS) or high temperature fiberglass (Ordering Code HS) wire insulation to increase the wire’s resistance to abrasion, mechanical and physical damage. It may be applied to 14 through 30 gauge conductors. Other overbraid materials such as Inconel* are also available by special order codes.

*Special Metals Corporation Trademark

Refrasil - RR

Vitreous silica is applied on both positive and negative conductors with a vitreous silica outer jacket. Refrasil is typically not color coded. Used in high temperature applications, including furnace, load thermocouple and traveling thermocouple applications. Moisture and abrasion resistance only fair. Offered in thermocouple grade. Available with SAE AMS 2750 compliant calibration data. Temperature rating: Continuous: Up to 1600°F (871°C). Intermittent: Up to 1800°F (982°C). We recommend stainless steel or other overbraid with this wire.

Nextel - NE

A high temperature ceramic fiber is applied over each conductor and then overall. Nextel is not colored coded. Although nextel is not recommended for use with platinum thermocouples, it can be used as an excellent option for other high temperature applications. Its use is limited by the temperature rating of the thermocouple wire it insulates. It is frequently used in furnace and traveling thermocouple applications. Available with SAE AMS 2750 compliant calibration data. Temperature rating: Continuous: Up to 2200°F (1200°C). We recommend SS overbraid with this wire.

| Thermocouple Type | Material | Magnetic | ASTM Color Coding | IEC Color Coding |

|---|---|---|---|---|

| J |

Iron

Constantan |

Yes

No |

White

Red |

White

Black |

| T |

Copper

Constantan |

No

No |

Blue

Red |

White

Brown |

| K |

Chromel

Alumel |

No

No |

Yellow

Red |

White

Green |

| E | Chromel/Constantan |

No

No |

Purple

Red |

White

Violet |

| P | Platinel | N/A | N/A | N/A |

| S |

Platinum 10% Rhodium

Pure Platinum |

No

No |

Black

Red |

White

Orange |

| R |

Platinum 13% Rhodium

Pure Platinum |

No

No |

Black

Red |

white

Orange |

| B |

Platinum 30% Rhodium

Platinum 6% Rhodium |

No

No |

Grey

Red |

White

Grey |

| N | Nicrosil/Nisil |

No

Slightly |

Orange

Red |

White

Pink |

| C | Tungsten 5% Rhenium/ Tungsten 26% Rhenium |

No

No |

White

Red |

N/A |